At least 22 workers were killed in a South Korean factory fire in June after multiple batteries exploded, underscoring the ongoing safety failings within global supply chains. Many of the workers killed were Chinese nationals, and data shows foreign migrant workers may face higher risks of hazardous working conditions due to various complexities like language barriers and lack of proper training.

This fatal incident is one of a grim growing trend, as data from EiQ, our supply chain intelligence platform shows workplace health and safety incidents have been on the rise in recent years.

Identifying health and safety risks early through EiQ

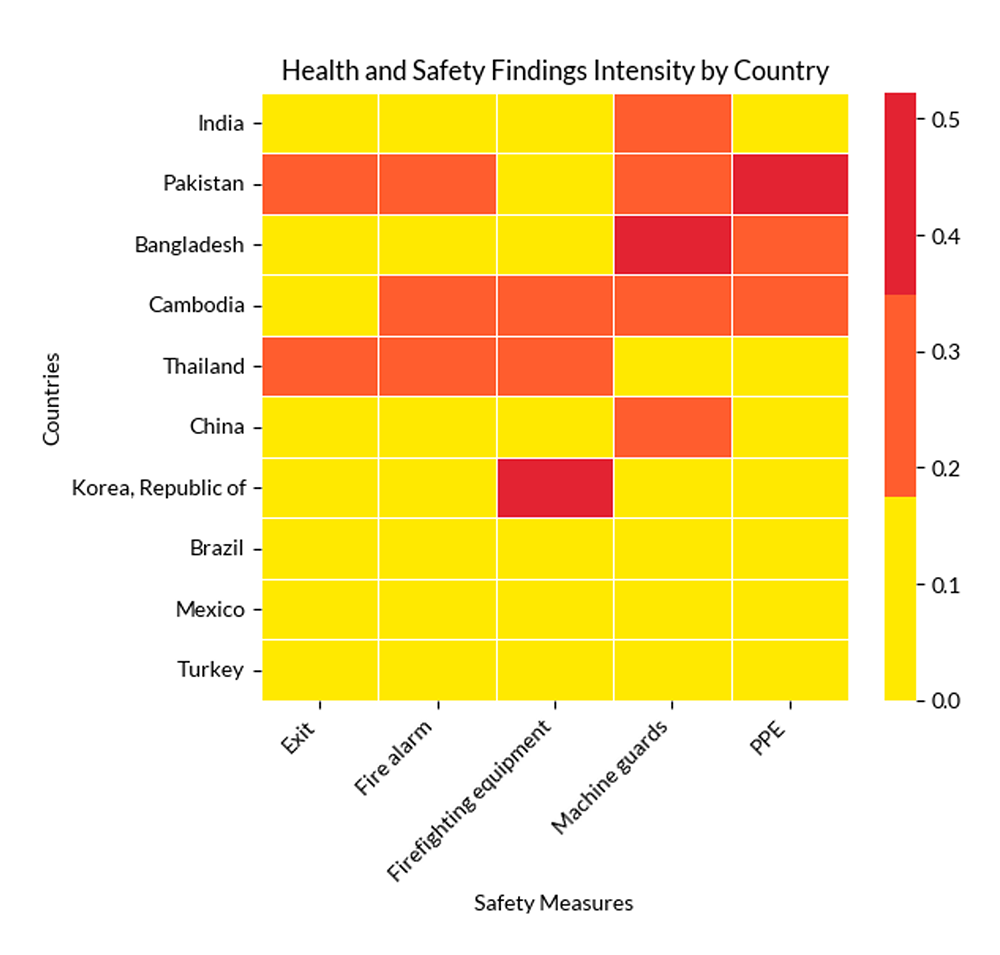

At least 94 sourcing countries showed high or extreme risk for health and safety violations in 2024, according to EiQ data, and the International Labor Organisation (ILO) estimates at least 2.3 million workers die every year due to work-related accidents or diseases.

Unsafe working conditions may often go undetected as public awareness tends to be focused on forced labour and child labour violations in supply chains. Businesses also lack visibility over suppliers, as sporadic audits may not provide a true reflection of a site’s conditions. Deadly incidents like the South Korean factory fire and the 2013 Rana Plaza disaster remind us that worker safety in global supply chains must be prioritised - and urgently - to prevent further tragedies.

Although annual audits may create time lags for businesses monitoring health and safety trends in their supply chain, advanced technology and robust datasets can supplement the gaps and support near-real time monitoring of these violations.

South Korean suppliers show worsening health and safety violations

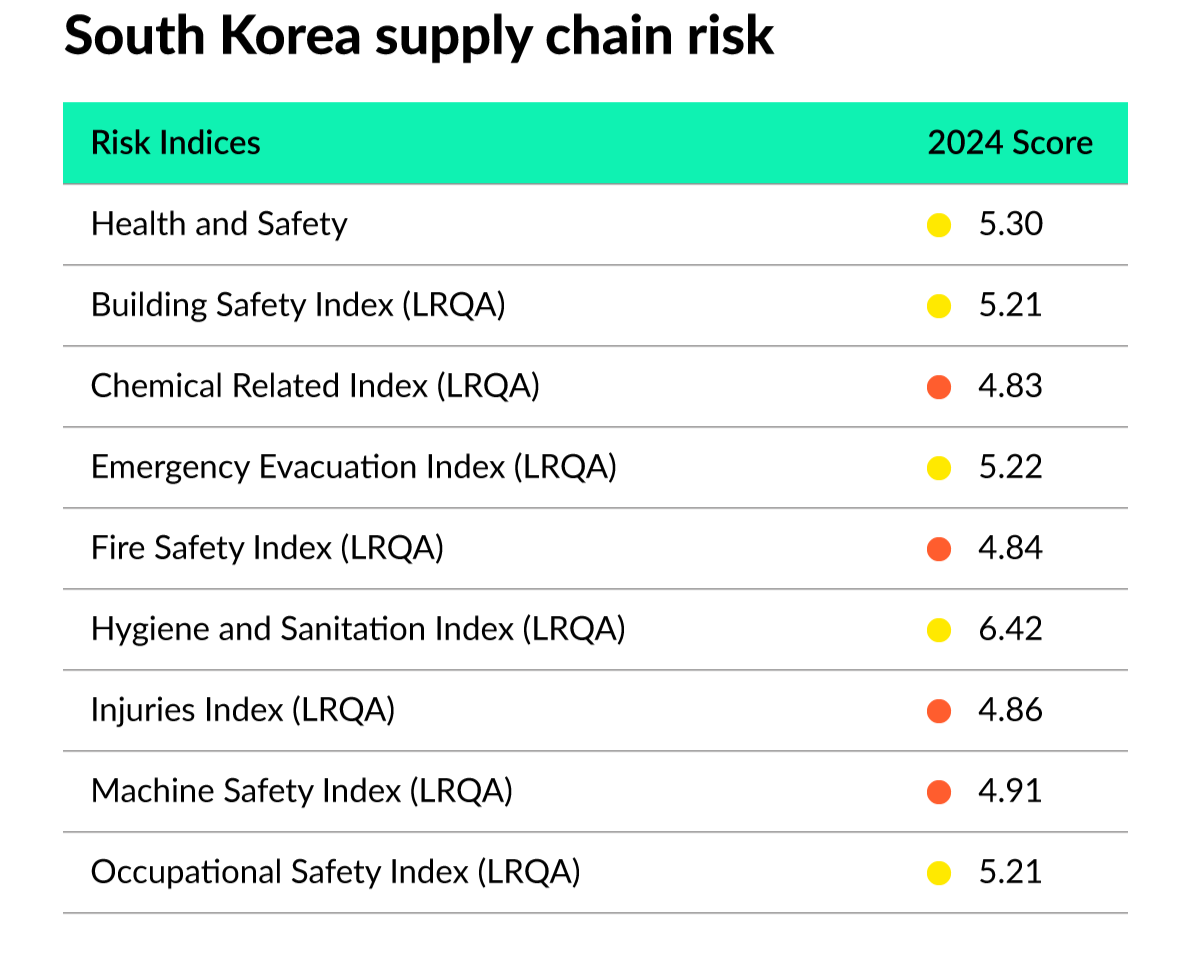

South Korea showed declining health and safety scores in EiQ in the past year, indicating higher risk for associated violations. Audit data in the country showed specifically high-risk categories were fire safety, chemical-related issues, and injuries. This could be due to South Korea's high-pressure work environments, particularly in sectors like manufacturing, electronics, and shipbuilding. The intense focus on productivity often results in compromised safety standards and inadequate enforcement of existing regulations.

There have been numerous reported incidents of workplace accidents, fires, and other health and safety violations in South Korean factories and construction sites. High-profile cases, like the deadly factory fire, highlight systemic issues and contribute to the South Korea’s higher risk score for ESG violations.

Prioritising worker safety in global supply chains

We have seen the repercussions of unsafe working conditions for years, through tragedies like the deadly Rana Plaza disaster, which killed more than 1,100 workers in 2013 after a garment factory in Bangladesh collapsed. This ignited efforts to improve working conditions worldwide, but the issue persists. Worldwide, there are around 340 million occupational accidents every year, according to the ILO.

Our EiQ Sentinel tool identified more than 300 fire incidents, including some fatal incidents, in 2023 and 2024 alone across 34 countries. Fire incidents and fatal injuries are rarely reported through standard audits, highlighting the need for beyond audit measures to properly assess health and safety risks on sites.

Businesses have an ethical obligation to ensure that their operations do not harm employees and to ensure they are complying with international standards and oftentimes regulatory requirements.

Ensuring safe working environments demonstrates a company's commitment to ethical practices and compliance with international labour standards, thereby enhancing its reputation and fostering trust among stakeholders, including consumers, investors, and governing bodies. Health and safety violations can disrupt production and supply chain continuity, leading to delays, increased costs, and potential loss of business.

Addressing these vulnerabilities requires comprehensive strategies, including robust legal protections, targeted health and safety training, accessible reporting mechanisms, and efforts to integrate migrant workers into local communities. By prioritising the health and safety of migrant workers, companies can mitigate ESG risks, enhance workforce stability, and promote ethical supply chain practices.

Contact us to better understand your supply chain needs.